جمع صورت حساب : 0 تومان

سبد خرید

گروه محصولات

- سنسور

- پالایشگاه

- دورههای رایگان

- English

- کالای دیجیتال

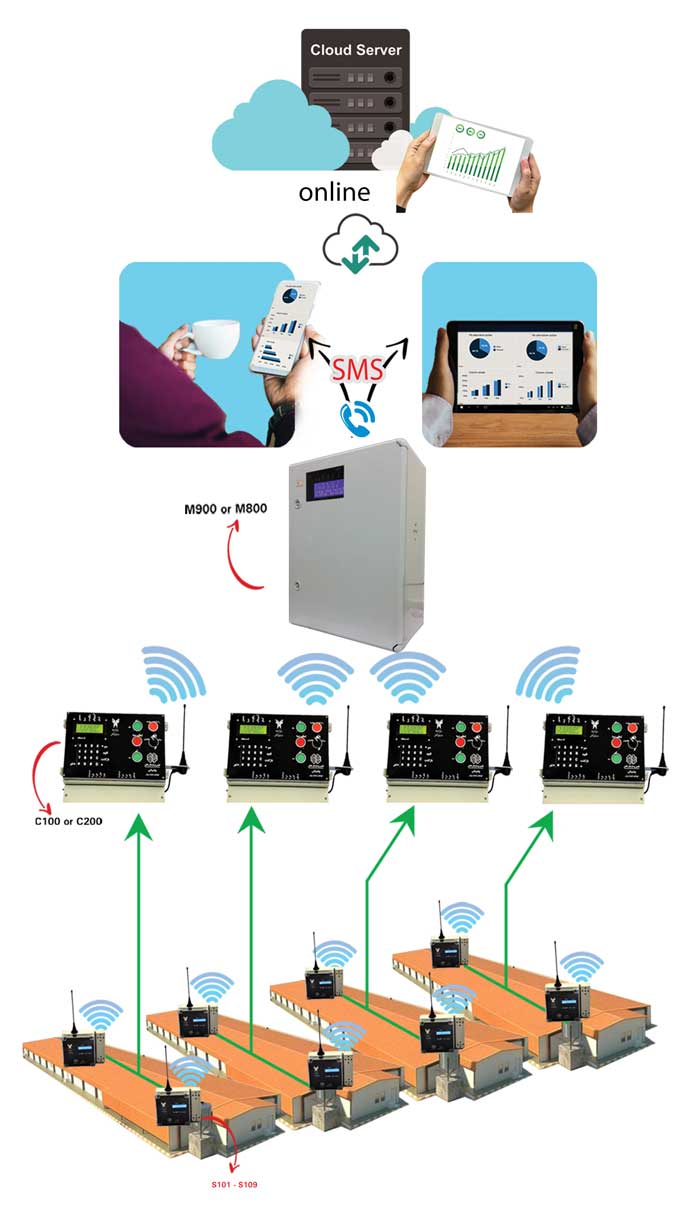

To achieve maximum production and better products, Smart climate control should be used in poultry house that includes: Temprature sensor, humidity sensor, ammonia sensor, monitoring system and etc.

1x Humidity and Temperature and NH3 sensor

1x Controller

1x Monitoring system

24 month warranty

Call us for the price information

The poultry automation complex of the Alertis N16 model includes:

1x Humidity and Temperature and NH3 sensor

1x Controller

1x Monitoring system

Monitoring and Controlling environmental parameters such as temperature, humidity, ammonia gas, and so on are important in poultry farming that this observation and control should take place 24 hours a day, over a chicken breeding period of 40 to 45 days, in a precise manner; It is impossible to see the monitor for twenty-four-hour in a day by person and even if this is possible, the precision in the observed parametric analysis would not be possible.Therefore, it is necessary to have a system that can send SMS at the moment of danger based on the information received and analyzed.

System features:

The poultry automation, which is the heart and center of the whole poultry hall, brings comfort and peace to the poultry owners, which we have outlined some of them below:

Eliminate all manual control steps and reduce employers costs

Reduce Energy and fuel consumption

Increase Efficiency

Decrease in human traffic to prevent diseases

Avoid any mistakes, negligence, etc.

All this makes automation in a poultry a necessity and no longer a luxury system.

Automation techniques can be used to monitor temperature, humidity and gases such as ammonia to optimize energy use.In fact, the more accurate the measurements are, the greater the capability of automation and can manage more precise operations.

The cost of automation for poultry farms was not significant given the cost of their energy consumption and It can be said that a sophisticated automation in a poultry season will easily offset the energy savings. In addition, automation equipment does not require general maintenance and can serve poultry for many years without error.

Poultry automation, in addition to reducing energy costs, can lead to a reduction in casualties to reduce the casualty rate to zero.

Poultry automation can affect production rate and increase production quality due to precision of intervals.

Poultry automation is also capable of communicating with poultry on a mobile basis to automatically be the first person to be notified if a poultry accident occurs.

Devices that can be used to automate a poultry farm include:

1.Temperature control and monitoring

2.Humidity control and monitoring

3.Gas control and monitoring

4.Air Conditioning Controller

5.Heating control

6.Cooling control

7.Control of smoke and fire and pollutants

8.Telemetry and Remote Control and Alarm Systems

Below we review some of the above and its importance in the poultry automation system.

Temperature control system:

The system has special sensors that measure the temperature of the salon at any given moment and as soon as the temperature goes off the permissible range it can turn on and off cooling-heating-window-opening jacks and air conditioners to Allow the temperature remain within the specified range.

Humidity control:

One of the factors that is important in addition to temperature in poultry is humidity. that decreasing or increasing moisture will actually cause different problems for the poultry, so automation can completely eliminate this problem.

Ammonia gas:

One of the pollutants in the poultry environment is the ammonia gas from waste, if the concentration exceeds the permissible level, causing respiratory problems for workers as well as birds and in high amounts, it restricts bird growth and imposes huge losses on poultry. With using an ammonia control system, this control is 24 hours a day and with suitable setting it can always work in standard range.

According to Field Report for this system, fuel and energy consumption has been reduced by one third by modifying the intelligent ventilation and control (automation) structure of poultry-poultry farms and performing minimum ventilation and fuel and energy consumption.

On average, fuel consumption has reached one liter per breeding season. This indicates that the poultry industry consumes about three billion liters of gasoline per year and has the potential to save one billion a year.

On average, a 50 to 70 percent reduction in poultry farming area is evident and has a significant impact on reducing the price of the product and will bring benefits to producers and consumers.

Also, this modification has resulted in increased productivity per unit area because due to proper littering and smart control at the farm area the incubation rate per unit has increased from 10 to 16 to 18 units on average and has provided the opportunity for efficient production of poultry.

This means that with the current capacity it is possible to increase production of more than 800,000 tons of poultry meat and reduce the price of the product.

This system has the potential to reduce losses and reduce consumption of don, medicines, etc., as most unit losses peak after four weeks (due to inadequate ventilation) and cause serious damage to poultry.

Smart poultry farms and good ventilation provide the right conditions for breeding and in this regard, in addition to a 50% reduction in casualties from previous periods and a reduction in consumption of at least 200 grams don per chicken in each period and a significant reduction in medicine use, etc., it has also been shown to significantly improve the quality of poultry meat.in terms of healthy production and reaching world standards, infrastructure steps can also be taken.

Some of the significant features of this product are:

Breeding features of poultry automation:

Technical Features of Poultry Automation:

مزایا

Increase profits and decrease costs Reduce consumption of don Reduce consumption of medicine Reduce casualties Preventing heat shock for chickens Awake and reliable 24 hours a day in the whole breeding period Increase farm breeding index per duct One kilometer range No need for cabling Capable of sending SMS at the moment of danger

معایب

نظرات کاربران درباره NAPADA poultry Smart climate Control Alertis model N16

(0 نظر)نظر خود را بنویسید